The story of TCO Certified

TCO Certified is the world-leading sustainability certification for IT products. It includes a comprehensive system of up-to-date criteria, independent verification and a structured system for continuous improvement to drive real and lasting change.

Our story began more than 30 years ago when we introduced the world’s first global certification for IT products, focusing on energy consumption and emissions, which included an energy-saving sleep mode for computer displays. Since then TCO Certified has evolved, and it is now the world’s only global sustainability certification for IT products. Today, the certification includes a broad set of criteria covering the supply chain and the full product lifecycle. Criteria areas include hazardous substances, circularity, socially responsible manufacturing, environmentally responsible manufacturing, and much more.

Criteria in TCO Certified go beyond legislation and industry standards to challenge the IT industry and drive progress. A new generation of updated criteria and verification methods is developed every third year, to drive incremental change and push sustainability where it matters most.

TCO Certified is a tool that enables new steps toward a future where all IT products have a sustainable life cycle. Purchaser demand for certified products is the main driver for the transition. Here you can learn more about the story of TCO Certified, and how we can work together toward sustainable IT products.

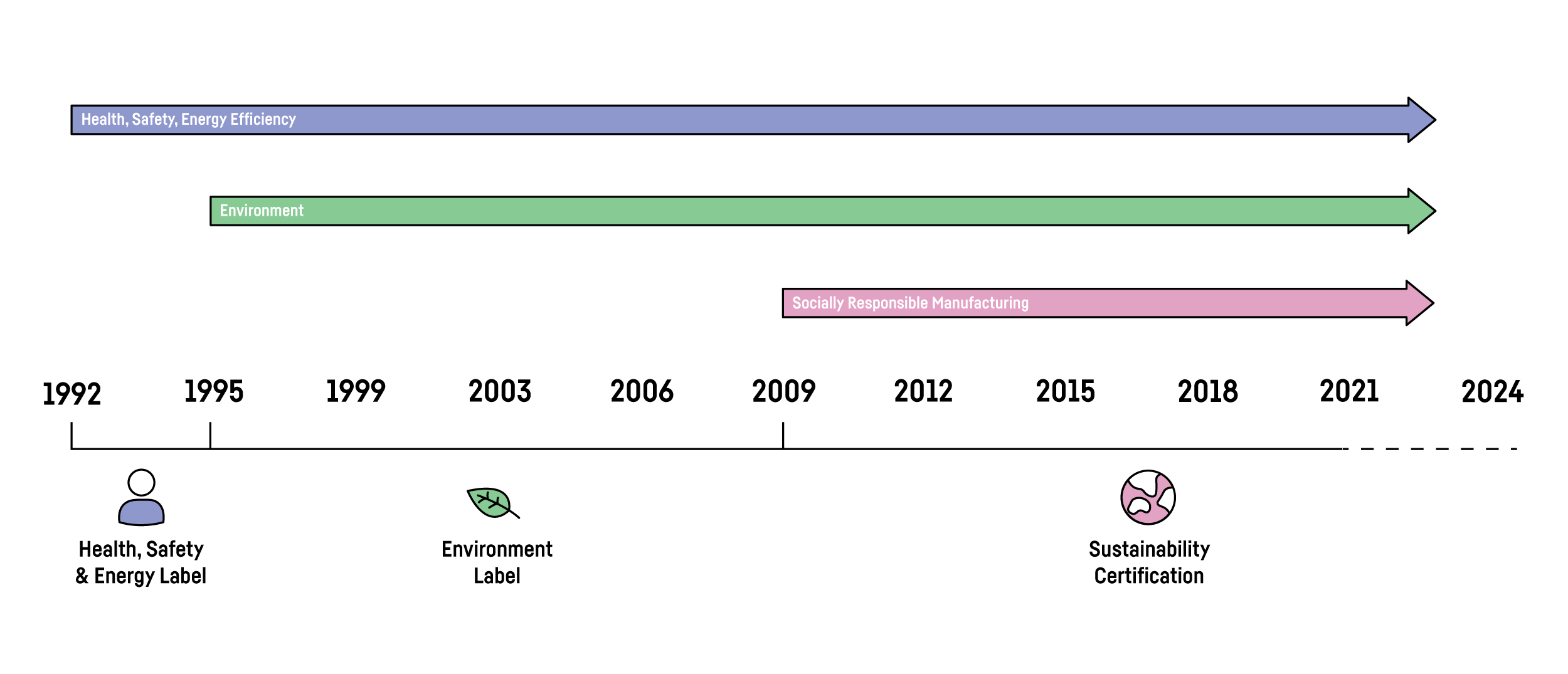

From safety to sustainability – the evolution of TCO Certified

1992

TCO’92 – world’s first global certification for IT products, focusing on environmental and health aspects

Computer displays are not energy efficient and emissions cause health concerns such as headaches. There is no system for regulating these issues or helping users choose safer products.

1995

TCO´95 – addition of hazardous content criteria, focusing on flame retardants and heavy metals; lead, cadmium and mercury

Growing environmental concerns around IT products, including hazards of flame retardants, bromines, and chlorinated substances. Legislation is slow and doesn’t address these challenges.

1999

TCO’99 – becomes the de-facto standard, combining environment with display quality. New criteria for visual ergonomics

With the introduction of flat panel displays, new image performance challenges emerge. Increasing concerns about product recyclability and manufacturer environmental responsibility.

2003

TCO’03 – expansion to mobile product categories, introducing criteria for ergonomics, product takeback and expanded ban on lead

Concerns around image performance and product adjustability. Hazardous content and toxic E-waste are growing environmental and human health challenges as mobile device usage grows worldwide.

2006

TCO’06 – continuous focus on environmental aspects but also moving image performance

Growth in video and online moving image content drive a need to ensure high performance picture quality, particularly with the growth in mobile products with a display.

2009

TCO Certified – the global sustainability certification for IT products. First to include criteria for socially responsible manufacturing

Increased awareness of poor factory working conditions in the IT industry. Issues with overtime, worker safety, forced labor and freedom of association receive worldwide attention.

2012

TCO Certified – broader, deeper sustainability criteria with increased verification and follow up of factory social responsibility compliance

Growing demand for industry to take action on social responsibility. Accountability for factory conditions is unclear and lack of industry transparency makes assessment difficult.

2015

TCO Certified – expansion of IT brand supply chain responsibility and social engagement. First list of safer, preferred flame retardants

IT brands expected to have overall responsibility for working conditions throughout the supply chain. With many hazardous chemicals banned, more knowledge is needed about safer substitutes.

2018

TCO Certified – a circular approach to IT products by demanding durable products that can be repaired, upgraded and recycled

Increased interest in a circular economy as a replacement to the linear way of producing and consuming products. Organizations want to contribute to the UN Sustainable Development Goals.

2021

TCO Certified — safer process chemicals, another step in circular IT management, and transparency further up the supply chain

The interest in sustainability is growing. Many organizations want broad-scope criteria that help them reduce risk, and see the lack of transparency in the IT product’s complex supply chain as a problem.

Driving sustainable development – the impact of TCO Certified

Organizations around the world choose TCO Certified as part of a sustainability strategy. Today, more than 10 600 product models from more than 400 IT manufacturers worldwide have been certified.

Energy efficiency

First to push for a solution to the escalating problem of energy consumption through “sleep mode” criteria for computer displays. Today, additional criteria cover a broader scope, including environmentally responsible manufacturing and product lifetime extension, to reduce energy use throughout the product life cycle.

Hazardous substances

Reduction or elimination of hazardous content, including chlorinated and brominated flame retardants, lead, cadmium and mercury. Improved transparency and control through the business-leading list for safer alternatives, TCO Certified Accepted Substance List.

Socially responsible manufacturing

Early to require IT manufacturers to demonstrate socially responsible production practices in the supply chain, including health and safety and labor rights. Our structured system for continuous improvements has led to progress in several challenging areas such as excessive working hours, forced labor and unfair wages.

Circularity

Driving the development of products that are durable, repairable, upgradeable and recyclable, making them more attractive for reuse or secondary markets. This way, the life of IT products can be extended, and e-waste levels reduced.