The transition to the circular economy is a paradigm shift that will require fundamental changes to how we approach materials, design, and use of products, as well as how business models are shaped to generate revenue. Today, a number of obstacles stand in the way of the circular economy. Overcoming them will require a dedicated, all-in effort that begins now.

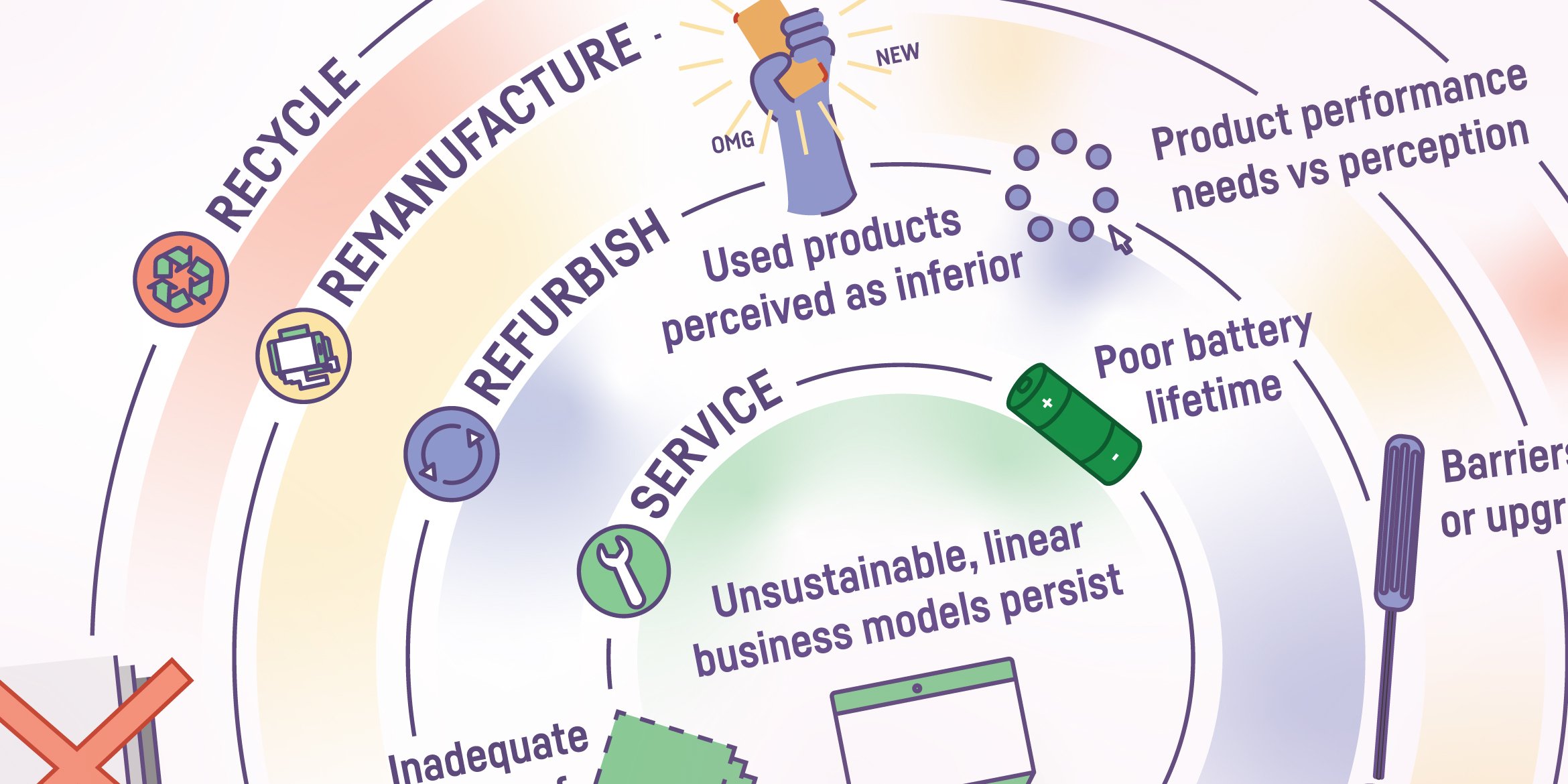

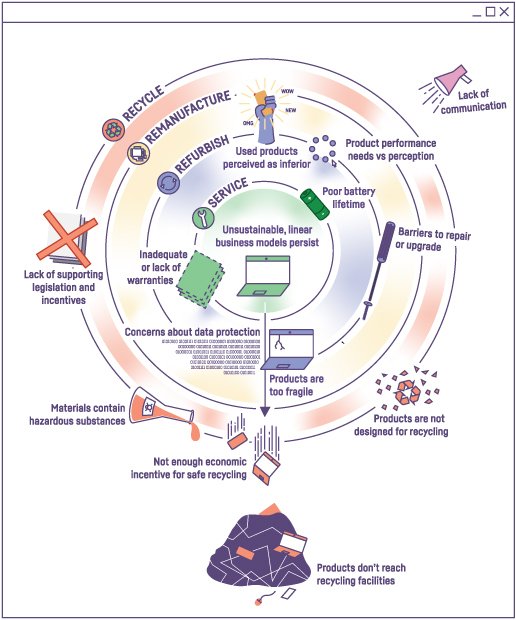

In a circular economy, the aim is to keep products and materials in use as long as possible. Products are designed for a long life and are durable, repairable and upgradeable. When products no longer can be used, materials are seen as resources that are reused in new products. The more a product can keep its original shape, the more it will retain its value, which is illustrated by the circles in the diagram. Circles closer to the user are more resource efficient than circles that are further out.

A lacking circular mindset, technical difficulties and not enough material reuse are some of the obstacles standing in the way of transitioning to a circular economy.

Lack of a circular mindset

Unsustainable, linear business models persist |

Linear business models where the purpose is to sell as many products as possible, are highly profitable in purely financial terms, but fail to account for the true costs of pollution and waste creation. These models must be replaced by circular models, for example where products are offered as a service.

Lack of supporting legislation and incentives |

In most countries, legislation that regulates how e-waste should be handled is lacking or very weak. This needs to change. Other ways of speeding up the transition to the circular economy include financial incentives that encourage the reuse of products, and that makes it economically advantageous to use recycled materials instead of virgin resources.

Used products perceived as inferior |

IT brands work hard to attract us to the most recent product models. Today, part of the positive user experience is owning something new, while reused IT products are often perceived as less attractive. Could users focus on functionality instead of looks, and could a second-hand or remanufactured product be perceived as a modern, conscious choice?

Product performance needs vs perception |

Until recently, computer software has continually required more hardware performance which has made IT devices obsolete after only two to three years. This is no longer true, and our mindsets need to change. By purchasing a high-performance product, you can keep it longer, or sell it to a second-hand owner.

Lack of communication |

While waste from one industry can be valuable for another, large amounts of resources are lost because of a lack of understanding and communication between different industries. A fully circular value chain requires collaboration between industries throughout the product lifecycle.

Technical obstacles

Concerns about data protection |

Fear of confidential data leakage results in many IT products being stored in drawers and basements instead of being made available for reuse. If manufacturers provide users with secure data sanitization software, this can be avoided. Many professional refurbishment companies also offer safe data removal.

Poor battery lifetime |

Portable IT products are often discarded because the battery has lost its ability to hold a charge, even though the product is otherwise fully functioning. Batteries should therefore be of good quality and be replaceable.

Barriers to repair or upgrade |

Too many IT products are discarded because of single components that stop functioning or that become outdated. We need to promote a repair culture, where products can be disassembled, repaired and upgraded with commonly available tools. Replacement parts and service manuals should be freely available.

Inadequate or lack of warranties |

A product warranty provides the brand owner with an economic incentive to design a high quality product. Once the warranty expires, the cost for repairing IT products is difficult for the purchasing organization to estimate, which may lead to those products being replaced. Extensive warranties encourage both durable product design and longer usage time.

Products are too fragile |

Mobile products are carried around in pockets and backpacks, which causes a lot of wear and tear. To enable a longer life, IT products must be durable and endure high and low temperatures.

Not enough material reuse

Materials contain hazardous substances |

Materials containing hazardous substances are unsuitable for recycling or use in new products. By replacing hazardous substances with safer alternatives, materials can be safely recycled and maintain compliance with increasingly stricter legislation.

Products don’t reach recycling facilities |

Only around 20 percent of discarded IT-products reach a safe recycling facility. The rest may end up in landfill, is incinerated, or illegally exported to regions where e-waste legislation is weak or non-existent.

Products and materials are not made for recycling |

Materials often lose in value in the recycling process. Materials that are present in very small amounts are difficult and costly to extract. Batteries can become a fire hazard in the recycling process if they can’t be removed and end up in the shredder.

Not enough economic incentive for safe recycling |

In many countries, it’s cheaper to export e-waste than to handle it domestically in accordance with stricter safety regulations. Virgin raw materials are often also cheaper than recycled materials since they don’t bear the full cost connected to the sustainability impacts in mining and refining. To make more high-quality recycled materials available on the market, environmental legislation must be stricter, and be enforced.