A robust ecolabel or certification makes sure that social and environmental issues are found and solved. However, banning bad practices does not necessarily lead to positive change. To avoid a situation where restricted behaviors are replaced with those that are even worse, we need to guide the industry toward safer, fairer alternatives.

IT products may contain a number of harmful substances, and workers in the IT industry are exposed to hazardous substances such as solvents in cleaning and assembly processes. The majority of these substances are not assessed for environmental or human health hazards. Also, working conditions in factories are an ongoing problem. Continuing risk areas include health and safety protection, forced labor, and excessive working hours. Addressing these challenges requires a number of measures, including product testing and factory audits — and of course it is important to ban elements that pose sustainability risks.

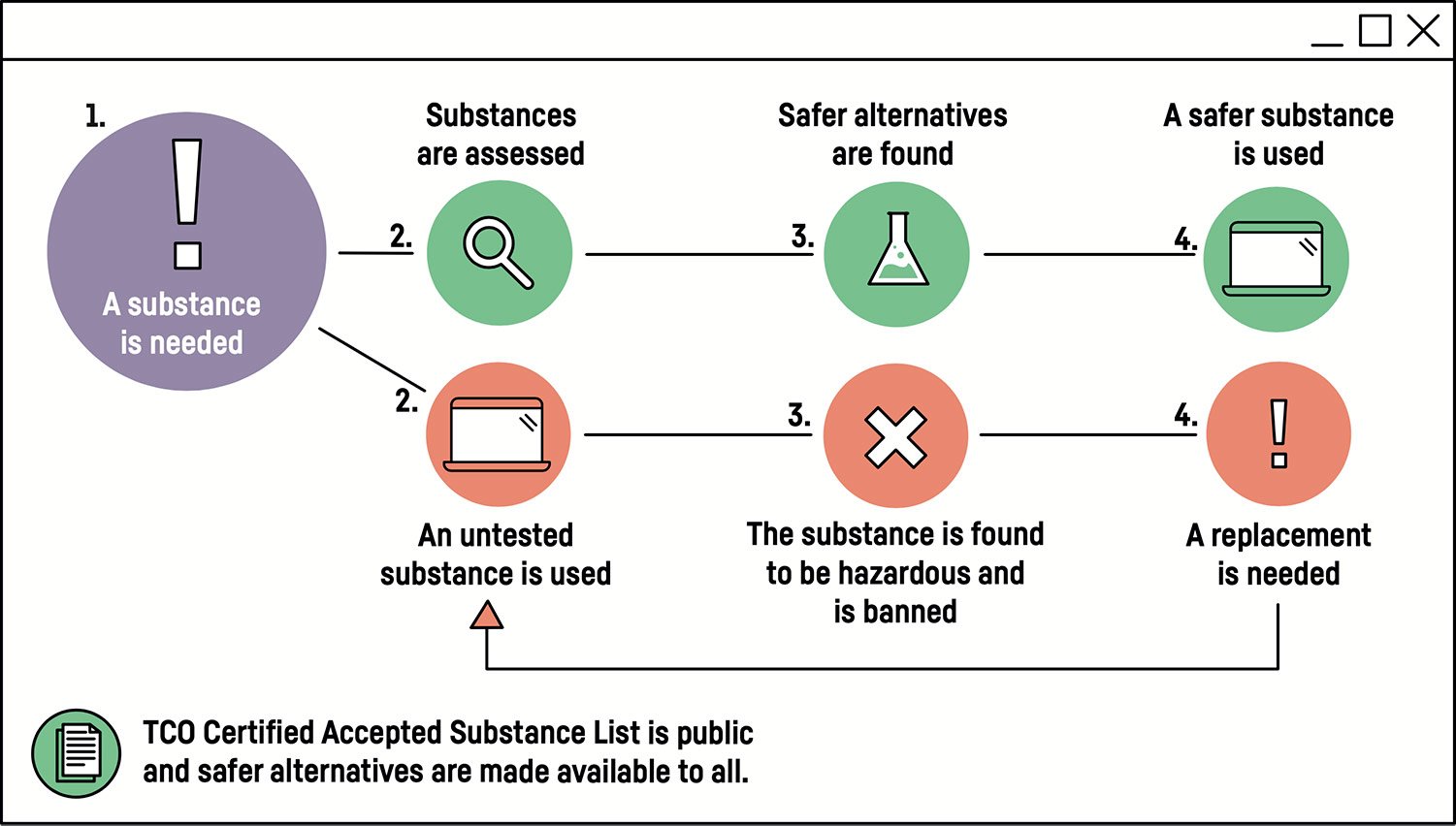

However, during our near 30 years in sustainable IT, we have seen that banning what’s bad is not enough. It easily turns into a game of cat-and-mouse, where what’s restricted is replaced by something else — which can be just as harmful, or worse. Legislation lags behind, so you need to be one step ahead.

These insights have led to the accepted list strategy that we launched in 2015. By guiding the IT industry to better and safer alternatives, we can avoid the detour via a number of bad alternatives, and increase the pace of sustainable development. Since the launch, our accepted list strategy has expanded and today it rests on two pillars: safer chemicals and more responsible factories.

TCO Certified Accepted Substance List – making safer chemicals the mainstream choice

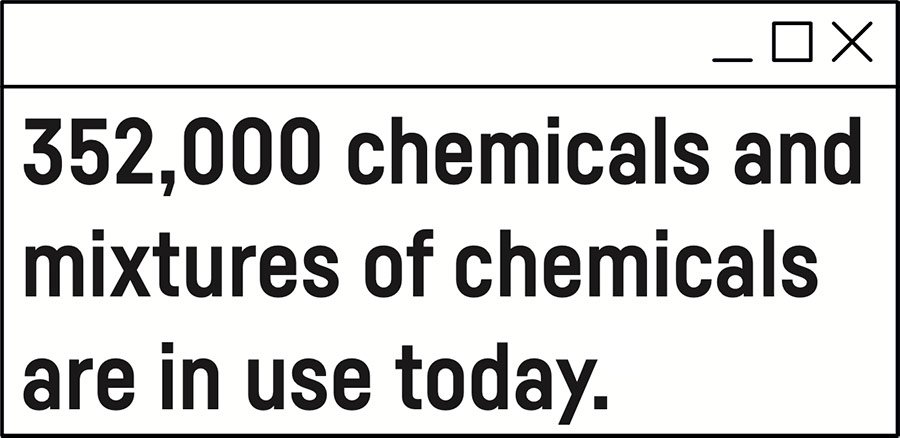

Nobody knows exactly how many chemicals are used in the IT industry today, but best estimates are in the tens of thousands. What we do know is that very few have been studied for their impact on humans and the environment. The introduction of new chemicals far outpaces the development of legislation to regulate them. Simply banning substances isn’t enough. We need better information about the substances that are being used to replace them.

With TCO Certified, a chemical is considered a high risk until it is proven to be otherwise. GreenScreen® for Safer Chemicals is used to identify a pathway to safer alternatives. Only plasticizers and flame retardants that are assessed as safer alternatives by an independent toxicologist are added to TCO Certified Accepted Substance List and may be used in certified products.

This way, regrettable, perhaps even more hazardous substitutions are avoided and safer alternatives are made the mainstream choice. Mark Rossi, Executive Director of Clean Production Action, the organization behind GreenScreen for Safer Chemicals, explains the importance of guiding the industry towards proven, safer chemicals:

“Just because a chemical is not on a restricted list does not mean it is safe. At least 1,800 known toxic chemicals and chemicals of high concern are insufficiently regulated in Europe and globally. The role of TCO Certified in moving IT companies to know the chemicals in their products and replace those chemicals with safer alternatives is critical to transforming the IT industry,” he says.

TCO Certified Accepted Substance List is dynamic and listed substances may be reassessed in the light of new scientific findings. All substances on TCO Certified Accepted Substance List are reassessed every five years to verify that the substance remains the better alternative when new data is available. If new data shows that a substance no longer meets the requirements, the substance is phased out and may no longer be used in products that are certified according to TCO Certified.

In 2021, the system for safer alternatives to hazardous substances will be expanded to include process chemicals used in the manufacture of IT products.

TCO Certified Accepted Factory List turns more sustainable practices into good business

Enforcing new practices in a gigantic, multifaceted industry spread across several continents is a challenge. We wanted to quicken the pace toward sustainable manufacturing and looked to develop more efficient methods than the ones we already had. Therefore, we launched TCO Certified Accepted Factory List as part of TCO Certified in 2018.

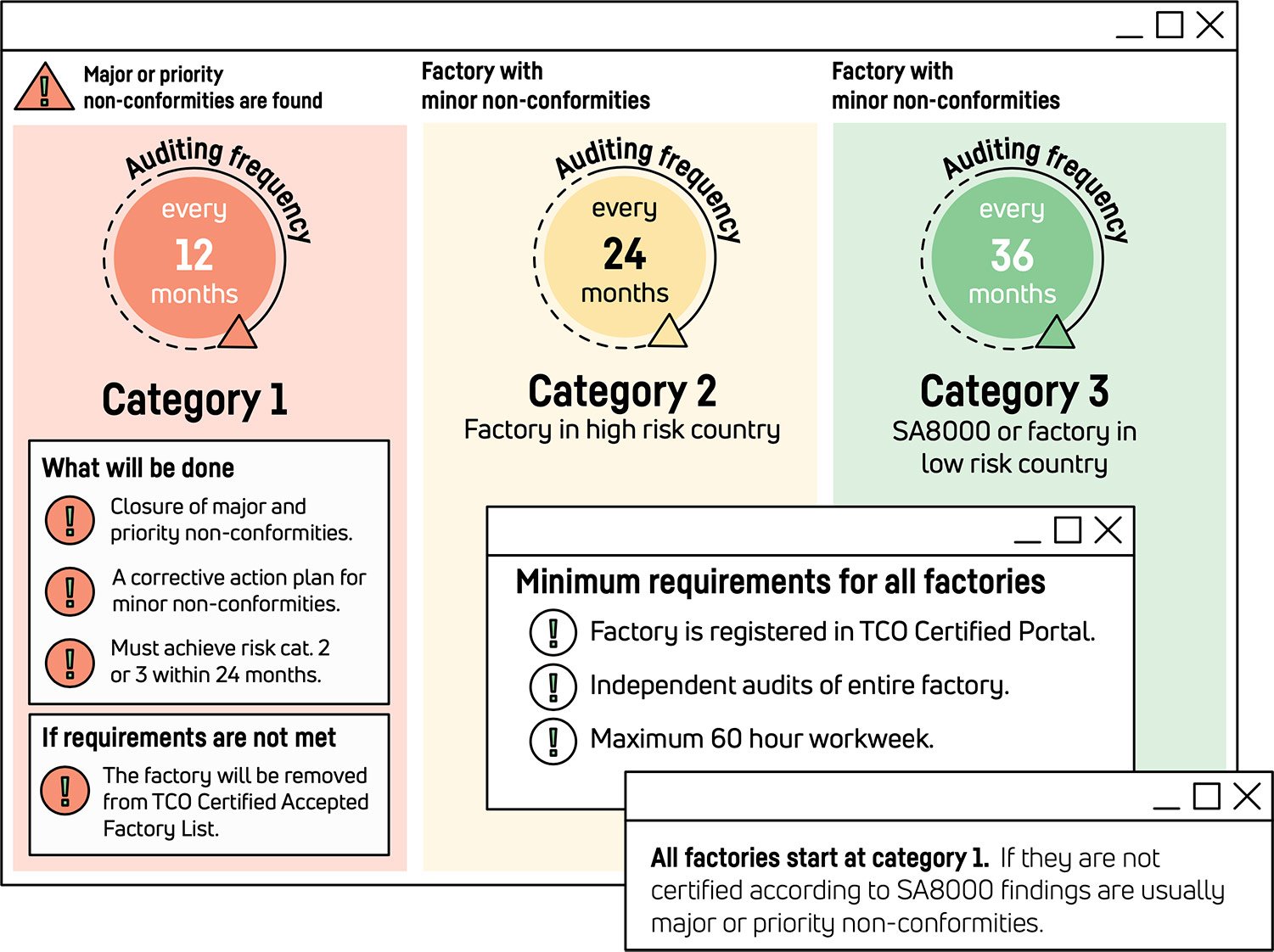

With TCO Certified Accepted Factory List, all final assembly factories that manufacture certified products are divided into risk categories. Those that are proactive in their work with sustainability, and continuously meet the criteria in TCO Certified are placed in a low risk category, while factories with persisting sustainability issues receive a higher risk category. If major issues are not corrected within a set timeframe, the factory is removed from TCO Certified Accepted Factory List, and is no longer allowed to manufacture certified products.

How TCO Certified Accepted Factory List works

This way of working increases transparency, which is essential for improvement, accountability, collaboration and fair competition. IT product brand owners can view the latest audit findings and corrective action progress, and choose to locate production of their products at a factory that is at the forefront of sustainability. This is groundbreaking: sustainability is now good business for factory owners. More ambitious factories get more business, which is an incentive for factory management to prioritize sustainability issues.

Another benefit is that brand owners that commit to the criteria in TCO Certified are more likely to share the same factories. Instead of trying to meet individual customer requirements that may contradict each other, the industry can then focus on making continual improvements that matter. The risk categorization also allows a more efficient scheme for auditing and follow-up, where stricter monitoring at high-risk factories drives faster progress.

In 2021, TCO Certified Accepted Factory List includes 79 factories. Since the launch in 2018, 32 factories have been removed from the list, the majority due to non-compliance with TCO Certified criteria. We have also seen that generally, factory performance has improved significantly, with safer working environments and fewer issues with excessive overtime. More factories are also making an effort to meet stricter audit schedule requirements necessary to maintain a SA8000 certification, to improve their risk category on TCO Certified Accepted Factory List.