Our annual assessment process helps the IT industry address complex supply chain sustainability issues and guides brand owners and their suppliers to more sustainable ways of working. The results from 2019-2021 show that brand owners see the value of being transparent as it helps them make faster progress.

Thousands of workers are engaged in the manufacture of a single IT product model, from material sourcing and component manufacturing to final product assembly. Much of it occurs in low-cost and low-wage countries, where worker protection is often inadequate, and social sustainability is a continuing challenge. Examples of areas that need improvement include living wages, worker representation and working hours.

Socially responsible manufacturing criteria were added to TCO Certified in 2009 and have since been updated and made stricter every third year. With TCO Certified, all criteria are mandatory, and compliance is independently verified. To get their products certified, brand owners must ensure that products and factories meet all criteria in TCO Certified. As the number of committed brand owners grows, more factories are covered by the criteria, and workers’ lives and health can improve. TCO Certified now affects over 200,000 workers on the way to more sustainable working conditions.

Yearly assessment promotes proactivity

In addition to meeting the mandatory criteria in TCO Certified, brand owners must prove a long-term commitment and work proactively with their suppliers to reduce sustainability risks. To follow up on this work, all brand owners must complete a self-assessment questionnaire once a year and provide supporting documentation to prove that the stated information is correct. They must also meet with an accepted independent social verifier in an annual interview to discuss the results before a final score – red, yellow or green – is set by the verifier. Green is considered best practice, yellow is considered best practice can be achieved with improvements, and red means program/practice is missing.

The questionnaire and interview are intended to help brand owners anticipate emerging risks and support their suppliers in addressing them. Once anonymized, we share the results with participating brand owners in a yearly report to help them gain new insights and move in the right direction faster.

The assessment process also benefits us at TCO Development. It gives us insight into the IT product supply chain and helps us measure maturity and engagement levels, compare results and develop new criteria with maximum relevance and impact.

Openness leads to progress

For brand owners, participating in the process is mandatory, but the level of transparency is voluntary. However, we notice that many see a benefit in taking part in the process in a fully transparent way as it helps them focus, improve their supply chain management systems, and make faster progress. All brand owners have been willing to discuss and share details on their supply chain management with TCO Development to improve their performance rating and learn where to focus on improving their supply chain engagement from year to year.

Sustainable progress happens faster if brand owners get involved with suppliers in a harmonized way. In the interviews in 2019-2021, some organizations asked us how they could work to improve transparency and alignment with their peers. This became a focus area in the development of TCO Certified, generation 9.

2022 and onwards: Improved transparency and harmonization

Ahead of the launch of TCO Certified, generation 9, we developed the self-assessment questionnaire to increase transparency and improve harmonization between brand owners. From 2022 and onwards, the assessment process identifies gaps in a better way and guides brand owners more clearly, as they implement the remaining steps needed to achieve best practice levels. With this change, brand owners have a guiding tool that helps them create programs for living wages, worker representation, working hours, and more. Our goal to achieve a harmonized level of brand owner responsibility in the supply chains of the certified products has never been more ambitious.

Progress and challenges in seven key areas 2019-2021

Below you’ll find result selections from the annual assessments carried out in 2019, 2020 and 2021. It includes 20 questions, which remained the same over the three years to get comparable results and track the development over time. This article highlights findings in seven key impact areas, including some with good progress and others where much remains to be done.

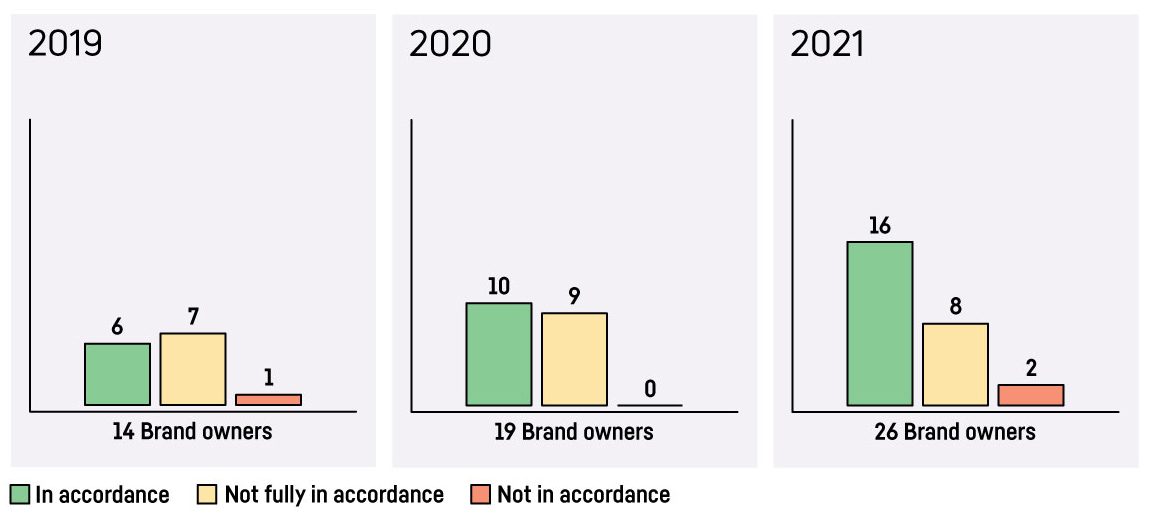

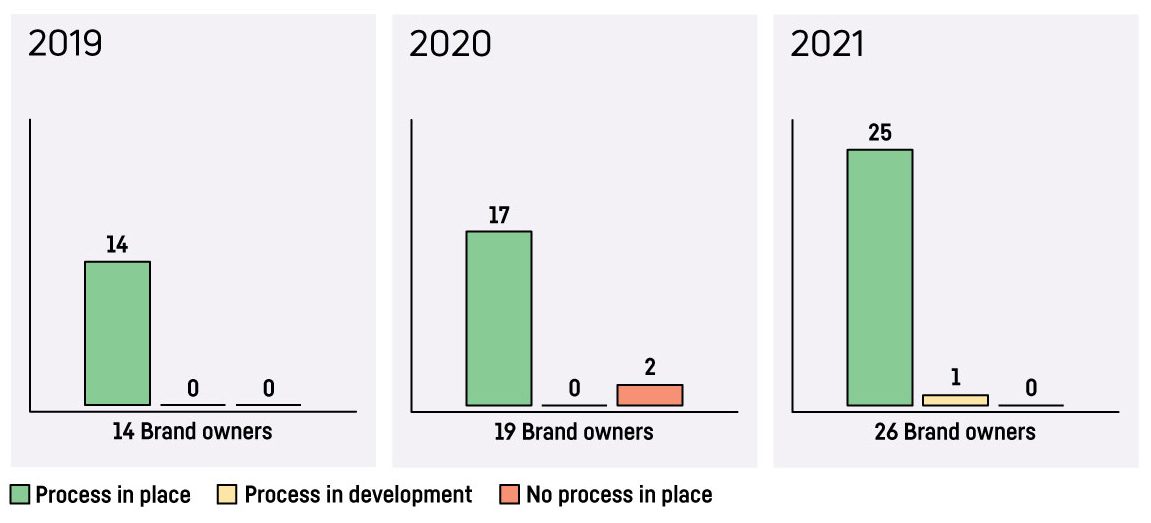

The number of brand owners with certified products has grown during the measured period, which means that the number of brand owners in the tables increases yearly. In 2019, 14 brand owners took part in the assessment process. In 2021, the number was 26.

Area 1: Supply chain due diligence process assessment

Supply chain due diligence is an important tool that helps organizations respect human rights and the environment in their supply chains. The OECD Guidelines for Multinational Enterprises is regarded as the due diligence framework that businesses should carry out to identify, prevent, mitigate and account for how they address actual and potential human rights and environmental risks in their own operations, supply chains and business relationships. A good management system shows how systematically a brand owner works with the supplier and indicates the level of influence they have to drive improvements in their supply chains.

- In 2019, 14 brand owners claimed they conducted pre-contract due diligence on suppliers. However, the assessment process discovered that only 6 of the 14 could prove that their due diligence process was consistent with best practice OECD guidelines.

- During 2020, 19 brand owners were assessed. Three of them were assessed to have improved their due diligence management system compared with the previous year.

- By 2021, the number of assessed brand owners had increased to 26. Two additional brand owners had improved their due diligence process since their first assessment in 2020.

- Those that had progressed to a green score continued to keep this level consistent in the subsequent annual interviews. Only two brand owners replied that they had no process in place during the 2021 interviews.

Supply chain due diligence process in accordance with OECD guidelines

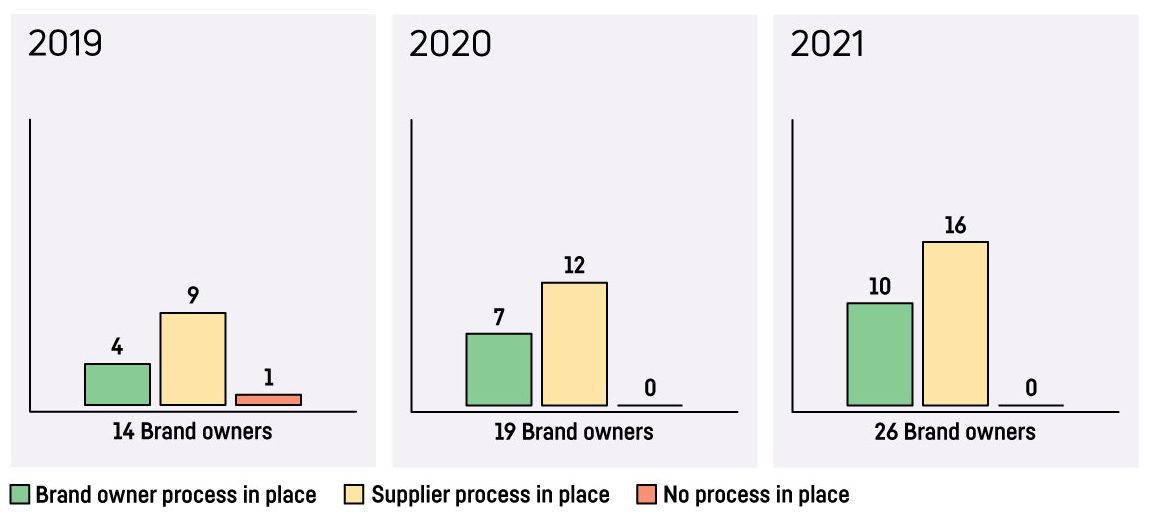

Area 2: Vulnerable worker remediation process assessment

Brand owners should be working to safeguard the rights of vulnerable workers in their supply chains. Young workers (16-18 year-olds), shall not work overtime or be exposed to work that is likely to be hazardous or harmful to them.

- In 2019, 4 of the 14 interviewed brand owners were assessed to follow best practice by taking direct action to make sure young workers were aware of their labor rights.

- By 2021, the 26 brand owners had been assessed, and all could prove they have a process for safeguarding at least the rights of young vulnerable workers. Ten brand owners of the total proved they were carrying out best practice by being directly engaged as part of a vulnerable worker protection training program they had developed. The remaining brand owners were providing tools and requiring suppliers to inform young workers of their rights.

Vulnerable worker remediation process

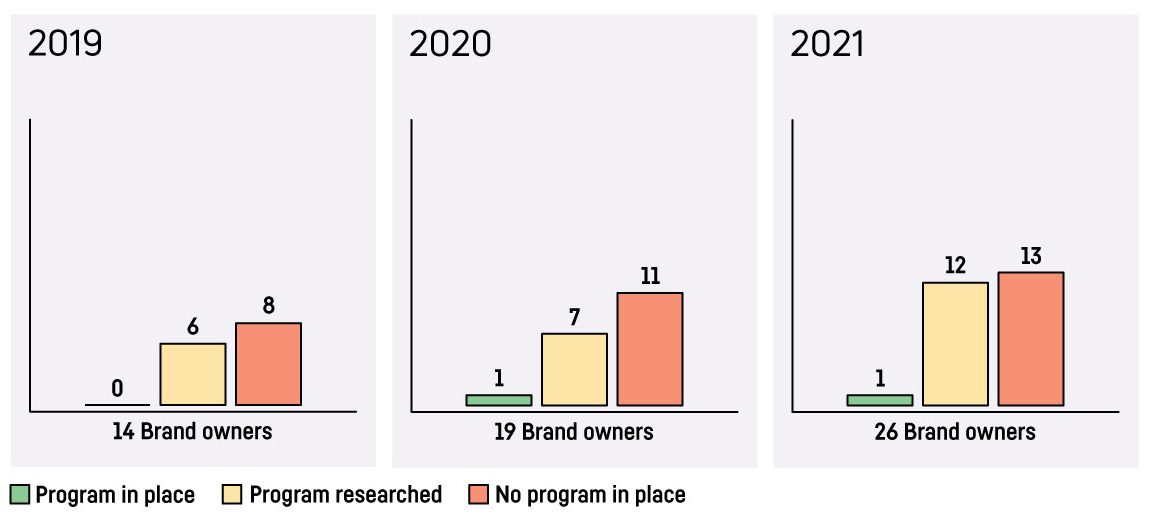

Area 3: Living wage program assessment

According to ILO conventions 131 and 26, a minimum wage should provide decent living standards to individual workers and cover a family’s basic needs. However, to achieve a basic level to live on, workers can be forced into situations where they must agree to work excessive overtime since working within local legal limits does not enable them to earn a living wage.

Minimum and living wages have the same objective, but are calculated differently. Minimum wages are set by governments that wish to stimulate employment and economic growth, whilst reducing poverty. Living wages for a worker are voluntary and calculations are only based on what is necessary to cover defined elements for a decent standard of living, such as family, food and housing.

Brand owners have claimed that it is not always possible for them to set wages at supplier level for all the workers at a supplier factory. As a result, many considered best practice was to support collective negotiations between workers and their employers, where wage ladder increases are based on the competence of the worker.

- In 2019, none of the 14 interviewed brand owners could provide credible proof of implementing a living wage program in their supply chains. Even though six brand owners could provide proof they were carrying out research, this did not lead to any implementation.

- In 2020, 1 of the 19 interviewed brand owners could prove it was modeling a living wage program at one of their own factories. However, this brand owner was assessed to have discontinued the program by the following year in 2021. In the same year another brand owner new to TCO Certified was independently assessed to be providing a living wage program. This time it was at a supplier factory not directly owned by the brand owner. This brand owner continues to be the only one that can prove they provide a living wage at a supplier factory.

- We conclude that although awareness and research has increased in this area, there has been no substantial improvement to implementing a living wage; and that reliance on increasing wages depends on limiting the amount of overtime available to workers whilst mitigating any income gaps that may occur when workers’ hours are limited.

Living wage program

Area 4: Process to avoid excessive overtime assessment

Brand owners should adapt their business to allow manufacturing facilities not directly under their ownership to avoid conditions that can generate excessive amounts of overtime for workers.

- From 2019 to 2021, the majority of brand owners were independently assessed to have a structured supplier procurement process in place to avoid situations that can lead to excessive overtime. In addition, several of them were monitoring compliance by collecting working hours and other metrics from suppliers. This usually had an impact on lines dedicated to brand owners, but not the amount of working hours in factories as a whole, which is what factory auditors look at.

- Due to this, and the continued situation of tolerated overtime well in excess of what is legal and healthy by suppliers and local authorities, it continues to be necessary for TCO Certified to limit the working week to 60 hours for all workers at the whole factory irrespective of local law. Although a 60-hour working week is the legal limit in some countries, it is less strict than in the major production country China, where local governments do not enforce working hours.

Process to avoid excessive overtime

Area 5: Factory worker representatives in supplier monitoring assessment

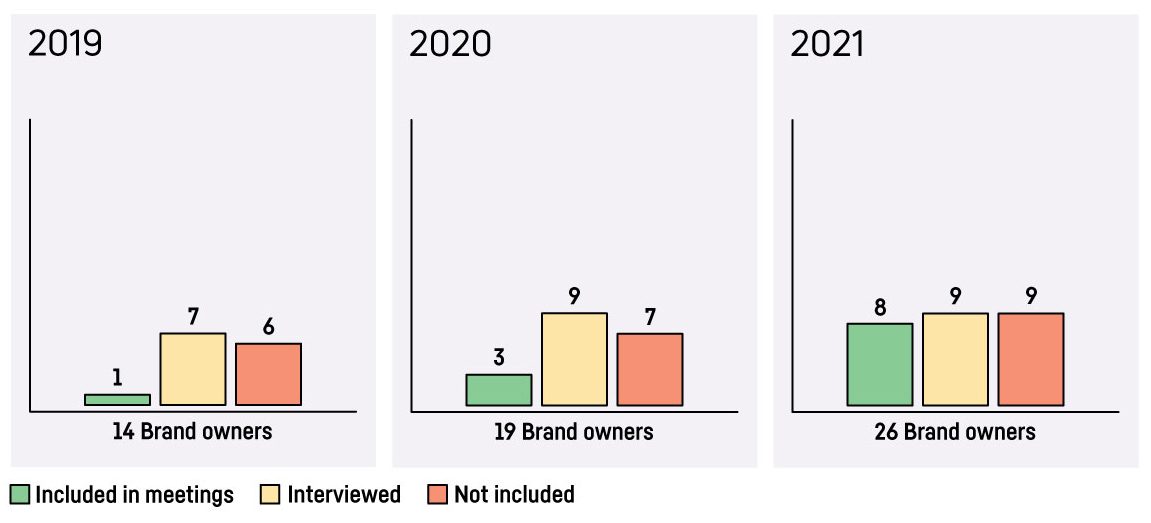

Worker representatives have an important role in facilitating worker/employee communication and should take part in the whole audit process as it gives them access to audit results and corrective action plans. The question evaluates to what level worker representatives are involved in the brand owner supplier monitoring process. To be scored green, the brand owner process must be considered to include worker representatives in interviews, audit opening and closing meetings and for audit results to be shared with the representatives. Yellow means the brand owner only interviews workers and worker representatives in their supplier monitoring process.

- From 2019 to 2021, there has been an increase in the number of brand owners that include factory worker representatives in the whole audit process, and make this a routine part of their management system.

Worker representative inclusion in audit process

Area 6: Grievance mechanism assessment

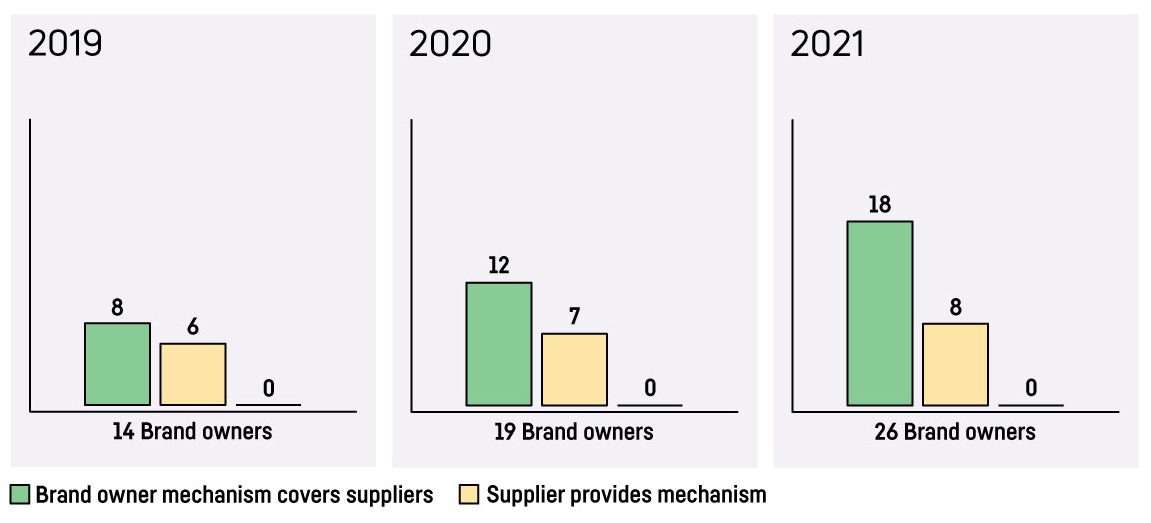

A grievance mechanism is a process for employees and other stakeholders to raise a complaint or report on deviations from a code of conduct.

- All 26 brand owners were assessed to have a grievance mechanism available to workers and a process of informing workers on how to report grievances.

- However, it’s been discovered that brand owner grievance mechanisms sometimes only cover workers directly employed by the brand owners and are not always extended to workers in their supply chains. In these cases, where a yellow score is given, the assessed brand owners require their suppliers to provide grievance mechanisms.

Grievance mechanism

Area 7: Working in collaboration to monitor and improve factory working conditions assessment

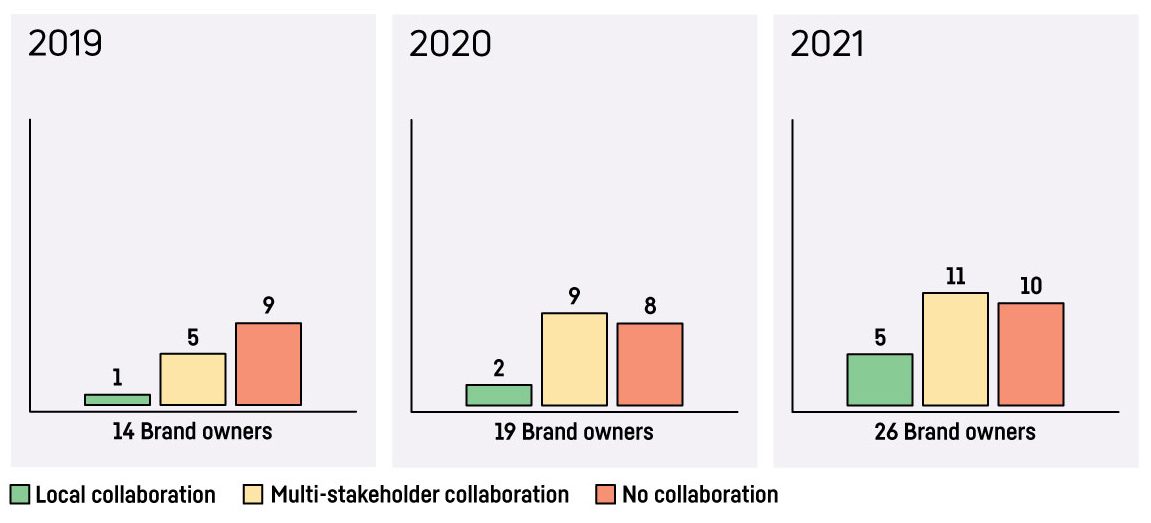

A collaboration with an independent body or worker representation group, such as a free trade union or local civil society organization (NGO), can play a crucial role in monitoring and improving the worker’s rights at the factory level. This is especially true where local authorities do not strictly enforce key labor rights, such as working hours and insurance payments.

- In 2019, only one brand owner was assessed as actively working with local NGOs.

- By 2021, eight brand owners were assessed to be in a working collaboration with a local group and worked directly with or consulted with them on worker involvement programs such as labor rights training or capacity building programs.

- However, the results show us that there continues to be reluctance or obstacles to collaborate. Instead of direct collaboration, many brand owners continue to work through multi-stakeholder forums that include NGOs to exchange information and collaborate on creating tools to help improve labor conditions.

Working in collaboration

Do you want to know more about how TCO Certified helps you address social issues in the IT product’s supply chain? Check out these articles on the issue and our solution, and contact us with any questions.