E-waste — a toxic waste stream where valuable finite resources are lost

E-waste is the world’s fastest-growing waste stream. Can you imagine that each year, our world produces over 100 times more e-waste than the weight of all children born that year? Add to that the fact that less than a quarter of all the e-waste produced is collected and recycled in a safe way.

According to the United Nations University’s Global e-waste monitormore than 60 million metric tonnes of electronic products are discarded every year. E-waste is the world’s fastest growing waste stream and the amount is estimated to increase to 82 million metric tonnes by 2030 unless this trend is reversed. There are several reasons for the increase. The world’s population is growing and economic prosperity reaches more people. Technological development is fast-paced and the price of IT products is dropping, leading to shorter product lifespans. Developed countries continue to contribute most to the problem, but developing countries are rapidly catching up.

Exported e-waste risk the health of vulnerable communities

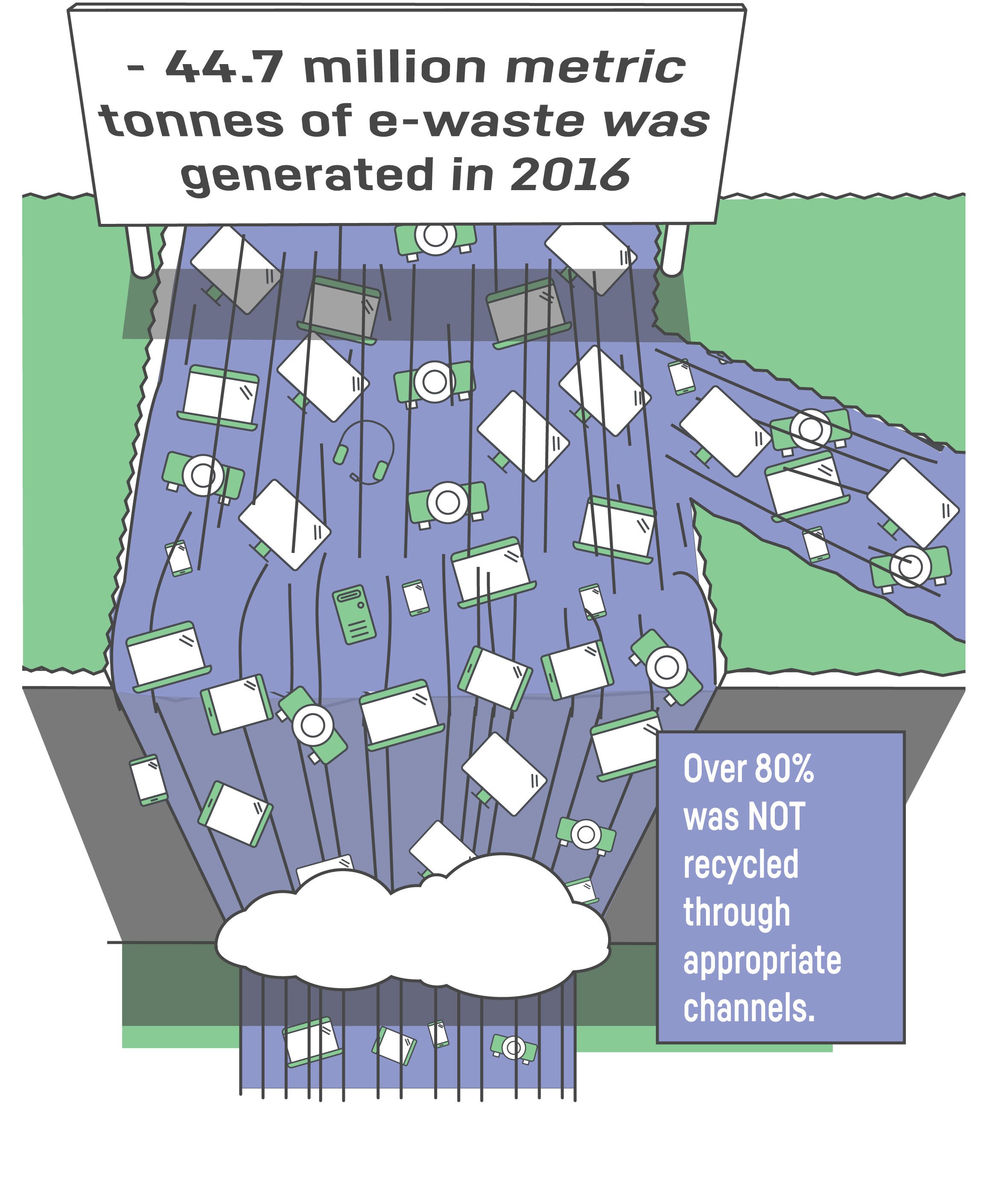

Most countries have difficulty handling these vast amounts of discarded products in a responsible and resource efficient way. In 2016, only 20 percent of electronic waste was recycled globally. While the focus has been on collecting products, not enough effort has gone into building infrastructure for processing the waste or safely recovering used materials. This has led to a shortage of facilities where e-waste can be managed safely. Instead, e-waste is mixed with residual waste, where it is often incinerated, placed in landfill, or exported to developing countries. E-waste exporters generally choose destinations lacking effective legislation that regulates how e-waste should be handled.

The export of e-waste is driven by two main factors: the demand for low priced electronics in the importing countries, and the fact that it is cheaper to export e-waste than to handle it domestically in accordance with stricter safety regulations. Western Africa and parts of Asia are common dumping grounds. In these countries, local populations make a living by extracting and selling valuable materials. Products are manually disassembled, burned in the open air or dissolved in acid by local laborers including children, without adequate protective equipment — leading to severe health problems. Electronic products contain a number of toxic substances hazardous to human health, with documented risk to the brain nervous system, lungs and kidneys as well as links to certain cancers. Toxic residues can leak and contaminate the soil, air and water, affecting surrounding ecosystems where the local communities grow their food, hunt and fish. The hazardous substances are also spread to other continents through the air and the sea.

A waste of valuable resources

Apart from being a risk to human health and the environment, the current way of handling e-waste has a negative economic impact. Electronic products contain a number of scarce, valuable resources, that are also essential for meeting our future product needs.

In 2016, it was estimated that electronic waste contained gold, silver, copper, platinum, palladium and other recoverable materials to a value of 55 billion Euros.

The circular economy — preventing e-waste and keeping materials in use

In the circular economy, products are designed for reuse over a longer period and waste is avoided. When a product has reached the end of its usable life, materials turns to valuable resources, used to manufacture new products. The goal is that no waste is produced. Instead, materials are kept in use and are reshaped over time.

For the IT industry, this means designing products that are durable, upgradeable, repairable and reusable. It should be possible to take them apart and vital components must be replaceable. Instructions for how to repair the product should be made available. It must be possible to delete data securely, so the product can be reused by a second owner without risk of data leakage. Also, the use of hazardous substances must be reduced or eliminated. Otherwise it may be difficult or impossible to recycle the materials when the product has reached the end of its usable life.

What you can do

If you need to buy a product, choose a model that is designed for a long life. It should be durable and withstand wear and tear and be possible to repair and upgrade. Try to use your products for as long as possible. This is the single most effective thing you can do to minimize e-waste and its negative effects on our planet. If it no longer fits your needs, consider if someone else might find the product useful. Sell it or donate to charity. Once the product has reached the end of its usable life, make sure it is recycled in a safe and responsible way.